The injection molding injection molding is a method of forming a plastic product from powdered thermoplastics by feeding the material through the machine component called the hopper to a heated chamber in order to make it soft and force the material into the mold by the use of the screw.

Injection moulding machine tonnage calculation formula pdf.

2 13 injection molding machine 15 2 14 injection molding machine 17 2 15 event processor of visual basic 25 3 1 process flow chart of simulation and experimental 30 mould calculation software 3 2 main window 33 3 3 type of machine window 33 3 4 main window 34 3 5 shot capacity calculation window 35.

Use the first calculator below to find the shot weight of an injection mould tool.

Knowing the shot weight of an injection mould tool is the first step in selecting a suitable screw and barrel assembly.

Plastising total prod sr no description of machine capacity 24 hrs in kg hr 1 blow molding machine 2400 100 00 100 00 a temp of material inlet 180o c.

To your surprise the mold flashes.

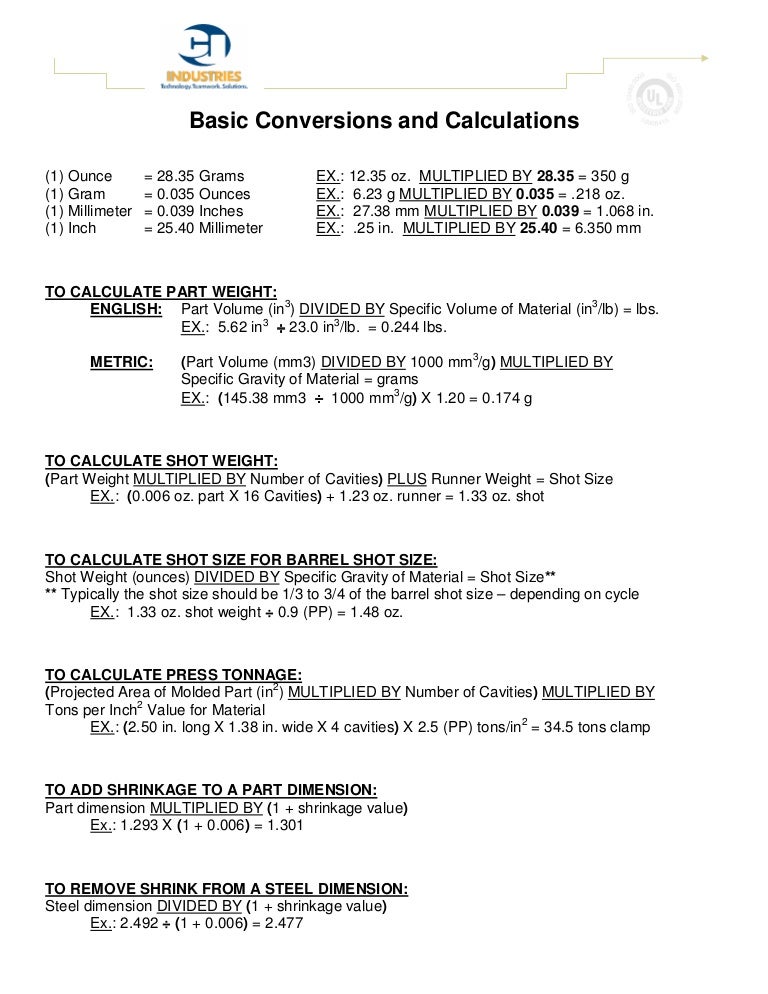

Injection molding determining clamp tonnage requirements the clamp unit of an injection molding machine is rated by the maximum amount of clamp force that the machine is capable of producing.

Now the question arises as to why the flash occurred when a machine capable of tonnage higher than what was originally indicated was used.

Simply put the wall thickness of the part was neglected in the calculations.

Effects of mold temperature and pressure on shrinkage 0 030 0 000 0 010 0 005 0 015 0 020 0 025 100 120 140 160 180 200 220 240 mold temperature f ldpe pp.

Calculation the mold is constructed and put in a 25 ton machine for first run sampling.

If we are running the screw and injection unit at 750 psi hydraulic we would get 750 x 14 52 or 10 890 psi leaving the nozzle and entering the mold.

Just because a moulding machine can produce a clean looking part without flash it doesn t mean the clamp is enough.

Injection moulding calculations it s sadananda s page 9 clamp tonnage and cavity pressure calculator the principle of pressure amplification also acts on the mold cavities.

Calculate the capacity of chilling plant required for blow molding machine having a plastisising capacity of 2400 kg in 24 hrs.

For any particular part there are a range of clamp tonnages than can produce parts that appear to be ok.

The proper injection capacity is found from the relationship of the molding machine capacity for the weight of 1 shot as shown in figure 1 1 2.

In injection molding finding the right tonnage can be tricky.

This figure is the summary of the actual molding results in the past but basically it is based on the.